This must be a new record... Another post within 24 hours!

The story about the engine at EBOS/Eptune needs to be continued. I have more material I need to publish soon so let´s get on with it.

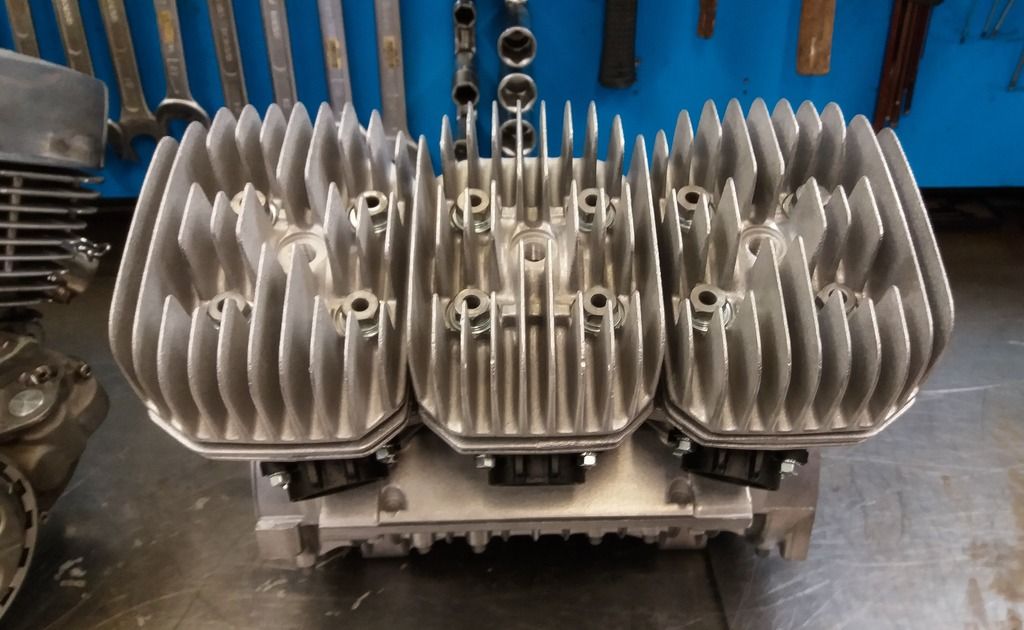

Yesterday I ended Part I with a picture of the engine assembled on the bench in Malmoe. Ebbe and I had a discussion regarding zink on the head bolts. He could see no sign of them being zinked originally so we left them in raw steel, glass blasted. If that was a correct decision or not remains to be seen. Easily fixed if not!

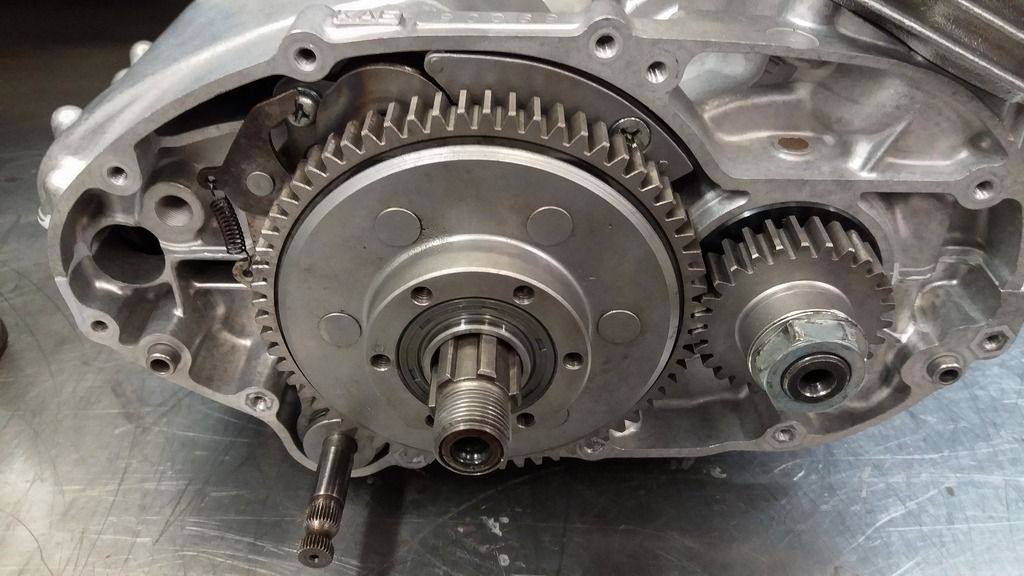

Now that the cases are together and the cylinders and pistons are taken care of, time to focus on the dry clutch. Ebbe sent me some parts for rezinking, remember? In the mean time he kept working on rusted and lost parts in the clutch area.

He had to manufacture one of these bushings. One was damaged by rust and the other one missing totally. I can tell you it feels good having a master mechanic working on such a are item as this engine. The O-ring seals between the bushing and the axle and the bottom of the needle bearing outside the bushings.

And here´s the other one he managed to salvage together with a new O-ring:

One of the parts I have been looking for all over the world for the last 6 months is the needle bearing inside the clutch inner hub. Absolutely no joy.... Solution? Guess who fixed one? Yeah. Ebbe got it!

He says I´m good at getting NOS parts, but he is a magician sourcing new, aftermarket, parts for these engines. If you ever trust him with one of your engines, don´t worry about bearings, gaskets and stuff like that. Either he has what´s needed in stock or he´ll find it somewhere.

In the picture above you can see the two bushings, O-rings and the brand new needle bearing carrying the inner clutch housing/primary drive gear once it gets on the shaft. You can also see why the surface of the axle actually isn´t that critical. The bushings take care of that!

The next picture shows the needle bearing inside the inner clutch hub/primary drive. The O-ring outside one of the bushings will seal together with the edge of the bearing you can see at the bottom there. Quite skilled engineering for the late sixties, early seventies.

This is what it´ll look like being mounted onto the shaft. O-rings on both sides of the bushings and an oil seal between the smaller, outer bushing and the outside of the inner clutch hub. Complicated? sure, very much so!

Here´s what the deal looks like assembled.

We can all appreciate the complications with a dry clutch.... You need to seal out the oil inside the clutch cover and still get a big shaft through, also sealed. I believe this will work fine!

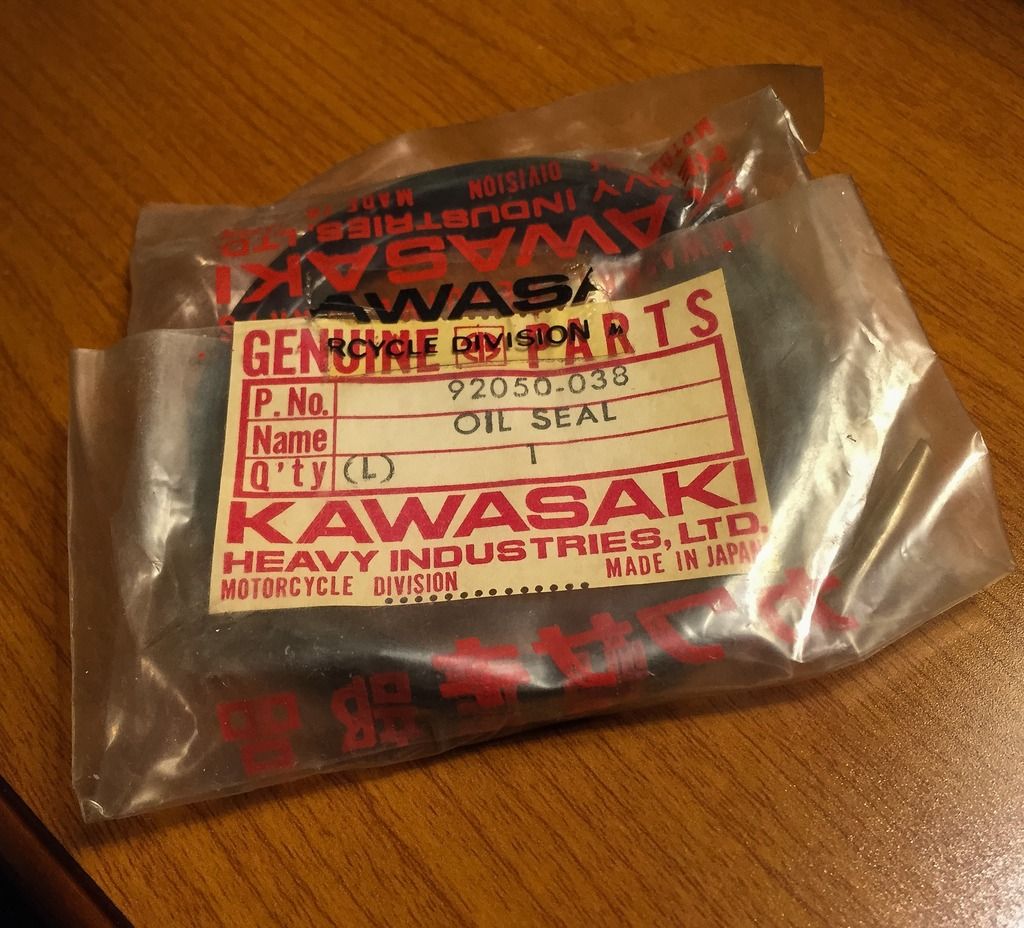

As you can see here it is soon time to assemble the clutch and put the cover on. The cover actually goes on first, since this is a dry clutch sitting on the outside... The need for another highly sought after parts became urgent...

The large oil seal that seals between the inner clutch housing and the clutch cover. Part number 92050-038. I have been looking for that one as well, since I bought the bike, back in May. A while ago I tried to set up a watch for the part number via eBay. It worked!

Just a few weeks ago I was notified someone had listed that exact part. I got the message on my cellphone, entered the eBay app and got it within 1 minute! Lord and behold! I got it!! and at a reasonable price. I love eBay at those moments. What´s even better is the guy had 4 of them, so I bought them all. These are good parts to have in stock, for sure!

These oil seals ent down to Ebbe last Friday together with the clutch parts, now rezinked:

You can see the engine case nuts ( I want the original ones...), the clutch outer housing, the lock washers (bought from Canada...!), the clutch spring holders and drilled screws and also the engine case oil plug. Also drilled for secure wiring!

Ebbe will get these parts tomorrow, Monday, and will probably have the engine ready by the end of the coming week. I can´t wait to go pick it up!

Next post when the engine is back home... If I don´t do something interesting to the bike before that!

Thanks for reading and as always, comments, questions are more than welcome!

The story about the engine at EBOS/Eptune needs to be continued. I have more material I need to publish soon so let´s get on with it.

Yesterday I ended Part I with a picture of the engine assembled on the bench in Malmoe. Ebbe and I had a discussion regarding zink on the head bolts. He could see no sign of them being zinked originally so we left them in raw steel, glass blasted. If that was a correct decision or not remains to be seen. Easily fixed if not!

|

| Heads mounted on the H1R engine. |

|

| Fabricated bushing for the clutch housing/basket. |

And here´s the other one he managed to salvage together with a new O-ring:

|

| Bushing number 2 saved by Ebbe. |

He says I´m good at getting NOS parts, but he is a magician sourcing new, aftermarket, parts for these engines. If you ever trust him with one of your engines, don´t worry about bearings, gaskets and stuff like that. Either he has what´s needed in stock or he´ll find it somewhere.

|

| New needle bearing found by the man, Ebbe! |

In the picture above you can see the two bushings, O-rings and the brand new needle bearing carrying the inner clutch housing/primary drive gear once it gets on the shaft. You can also see why the surface of the axle actually isn´t that critical. The bushings take care of that!

The next picture shows the needle bearing inside the inner clutch hub/primary drive. The O-ring outside one of the bushings will seal together with the edge of the bearing you can see at the bottom there. Quite skilled engineering for the late sixties, early seventies.

|

| Clutch needle bearing. |

This is what it´ll look like being mounted onto the shaft. O-rings on both sides of the bushings and an oil seal between the smaller, outer bushing and the outside of the inner clutch hub. Complicated? sure, very much so!

Here´s what the deal looks like assembled.

|

| No rust here any more...!! |

We can all appreciate the complications with a dry clutch.... You need to seal out the oil inside the clutch cover and still get a big shaft through, also sealed. I believe this will work fine!

As you can see here it is soon time to assemble the clutch and put the cover on. The cover actually goes on first, since this is a dry clutch sitting on the outside... The need for another highly sought after parts became urgent...

The large oil seal that seals between the inner clutch housing and the clutch cover. Part number 92050-038. I have been looking for that one as well, since I bought the bike, back in May. A while ago I tried to set up a watch for the part number via eBay. It worked!

Just a few weeks ago I was notified someone had listed that exact part. I got the message on my cellphone, entered the eBay app and got it within 1 minute! Lord and behold! I got it!! and at a reasonable price. I love eBay at those moments. What´s even better is the guy had 4 of them, so I bought them all. These are good parts to have in stock, for sure!

|

| 92050-038. |

|

| SC64769 or 92050-038. Quite big oil seal. |

These oil seals ent down to Ebbe last Friday together with the clutch parts, now rezinked:

|

| Rezinked and ready to go to Malmoe. |

You can see the engine case nuts ( I want the original ones...), the clutch outer housing, the lock washers (bought from Canada...!), the clutch spring holders and drilled screws and also the engine case oil plug. Also drilled for secure wiring!

Ebbe will get these parts tomorrow, Monday, and will probably have the engine ready by the end of the coming week. I can´t wait to go pick it up!

Next post when the engine is back home... If I don´t do something interesting to the bike before that!

Thanks for reading and as always, comments, questions are more than welcome!

Inga kommentarer:

Skicka en kommentar