It has been a while.... That is due to work. I´ve had my share of studying, preparing for and doing simulator sessions and training flights for the last month. Well, progress is happening also there and one day I may be able to relax and concentrate on the important things in life, Bikes! And my H1R...

Sorry to say, not much has happened for a while, but some things have been prodding along in their own pace. Remember I left the front fork inner tubes, stanchions, to be grinded free from pitting and rust a while ago. They were done at that first step about three weeks ago and here´s that story:

I left them at this place: B.L Slipteknik in the southern part of Stockholm. They do all sorts of precision grinding and sanding to very fine tolerances. Way better than needed for these stanchions! We had a long discussion regarding measurements and thickness of the coming layer of hard chrome versus the depth of the rust.... I should have brought the outer legs as well, but I did the next time. Sam is the man to talk to here. Great guy and very thorough!

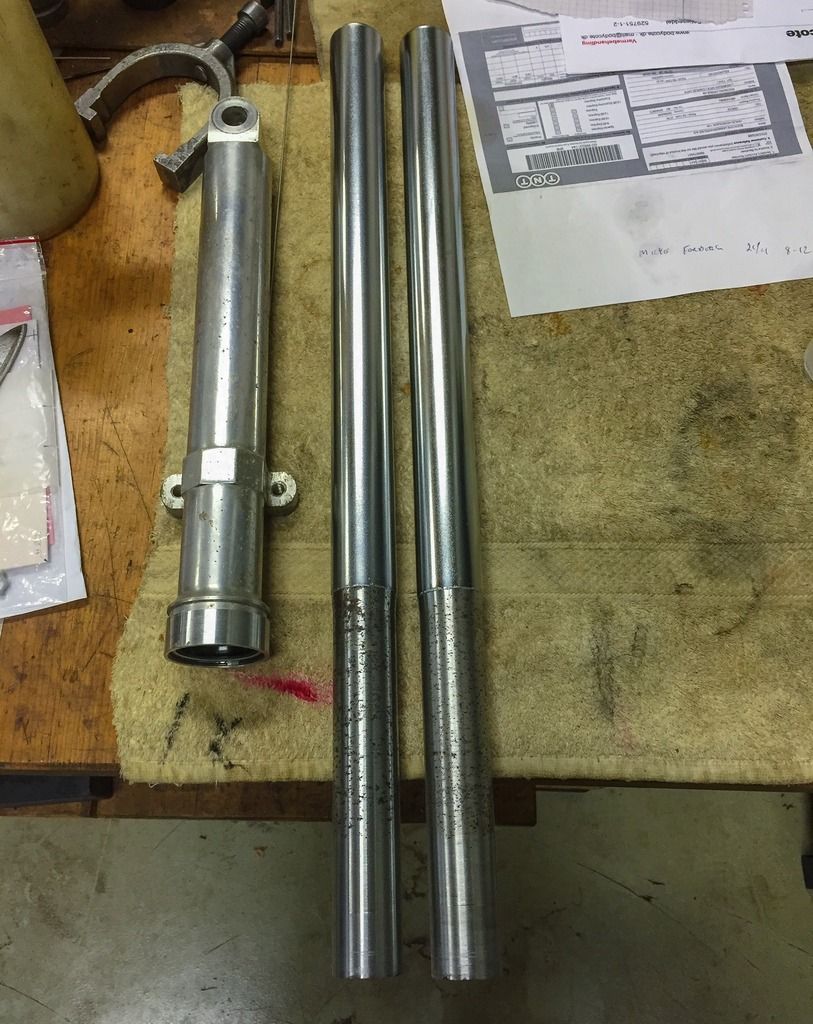

Since the frame was away for blasting and painting I was in no hurry at all, so they could take their time. They did. And that was totally fine.... I got a very fair price for that first clean-up and grinding. Here´s what they looked like when I went back to get them.

Sam had to remove about 35 hundreds of a millimeter to get the pitting and rust away. Approx 17 hundreds per side, so to speak. The rust on the top part of the tubes I will remove myself. That surface is not that important for the function of the fork. It is, however, tapered and difficult to set up in the grinder and thus quite expensive to work on. I can do that... This time I brought the outer leg as well. We needed to check the inner diameter of the outer tube and check what free play should be left between the parts. Anyone out there knows what free play is used in front forks?

To measure the inner diameter of the outer tube, Sam used the micrometer up front. It measures very accurately the roundness and the diameter of the tubes. Isn´t it wonderful with people who know their business?

That diameter was actually smaller than I had anticipated. 34.01 mm. Considering the inner tubes are supposed to be 34.00 mm it sounds very tight to me... That is easily controlled later when the tubes have been hard chromed and shall be ground to measurement in the end. More about that later. Next step.

Hard chrome is not the same as regular show chrome. It can be applied in much thicker layers and forms an extremely durable and hard surface that can take a lot of pressure and rubbing without giving way or getting scratched. One of it´s key features is it´ll grow in thickness in the electrolytic bath for as long as you keep it there. We decided to go up to 34.15mm to be sure we had enough herd chrome to grind off and form that perfect surface.

So, off to the hard chromer... I chose a business in Solna, just north of Stockholm, Fintlings. They have been around for ages and know their surface treatments. I knew this would not be cheap. I also knew it would take time... Surprise! Took less than a week and actually at quite a fair price. 4200 SEK, including VAT. A bit short of 500 USdollars for a rather thick layer of hard chrome. I´m happy it could be done locally!

OK, back to Sam in Jordbro! Here´s the result after Fintling´s chroming. We were both happy! Me, because I could afford it, Sam because their work was perfect! Not too much over chroming at the edges (that is a pain to grind off...) and also perfect thickness. Just right to be perfectly matched to the outer tube after the second grinding....

So, I left the tubes with Sam again... This time to be finished. Final grinding and a slight polish to that perfect "stanchion shine" Not too shiny but, for sure, free from pitting and rust.

Other than that, not much has happened on the project during the last month. I´m still gathering parts and trying to find missing bits and pieces. Extremely difficult! Not much around and people tend to keep stuff for themselves. I don´t blame them, I would do the same. The frame was finished a couple of weeks ago and sits on the lift ready to be assembled as soon as I can find the time for it. I also need to clean the fasteners and everything else for rezink.

Here´s what it looks like right now in the garage. Things piled up everywhere and the frame and parts sitting there, curing and waiting....

It doesn´t look too bad, though! Every time I pass it I want to start assembling stuff... I just have to be patient. There will be more time!

I recently had to empty another one of my small stashes of parts here on the island. That didn´t make it any easier! Now it is cramped for real! The H2 is going off to its new owner as soon as I can find the time to get it finished for him. That´ll ease up on things. My BMW R1200 GS and Wilma´s Z300 also have to camp in here. Plus the H1R project...

I NEED A BIGGER SHOP!!

Enough wining... Tomorrow I´m off for another training flight, This time to Chicago, my favorite town away from home. I feel at home most everywhere, but Chicago is special! Nice restaurants, nice people and that wonderful walkway along the lake.

When I get back I´ll start working on the wheels and the bolts and nuts...

Happy Easter everyone!

Your´s truly.

/Per

Sorry to say, not much has happened for a while, but some things have been prodding along in their own pace. Remember I left the front fork inner tubes, stanchions, to be grinded free from pitting and rust a while ago. They were done at that first step about three weeks ago and here´s that story:

I left them at this place: B.L Slipteknik in the southern part of Stockholm. They do all sorts of precision grinding and sanding to very fine tolerances. Way better than needed for these stanchions! We had a long discussion regarding measurements and thickness of the coming layer of hard chrome versus the depth of the rust.... I should have brought the outer legs as well, but I did the next time. Sam is the man to talk to here. Great guy and very thorough!

Since the frame was away for blasting and painting I was in no hurry at all, so they could take their time. They did. And that was totally fine.... I got a very fair price for that first clean-up and grinding. Here´s what they looked like when I went back to get them.

Sam had to remove about 35 hundreds of a millimeter to get the pitting and rust away. Approx 17 hundreds per side, so to speak. The rust on the top part of the tubes I will remove myself. That surface is not that important for the function of the fork. It is, however, tapered and difficult to set up in the grinder and thus quite expensive to work on. I can do that... This time I brought the outer leg as well. We needed to check the inner diameter of the outer tube and check what free play should be left between the parts. Anyone out there knows what free play is used in front forks?

To measure the inner diameter of the outer tube, Sam used the micrometer up front. It measures very accurately the roundness and the diameter of the tubes. Isn´t it wonderful with people who know their business?

That diameter was actually smaller than I had anticipated. 34.01 mm. Considering the inner tubes are supposed to be 34.00 mm it sounds very tight to me... That is easily controlled later when the tubes have been hard chromed and shall be ground to measurement in the end. More about that later. Next step.

Hard chrome is not the same as regular show chrome. It can be applied in much thicker layers and forms an extremely durable and hard surface that can take a lot of pressure and rubbing without giving way or getting scratched. One of it´s key features is it´ll grow in thickness in the electrolytic bath for as long as you keep it there. We decided to go up to 34.15mm to be sure we had enough herd chrome to grind off and form that perfect surface.

So, off to the hard chromer... I chose a business in Solna, just north of Stockholm, Fintlings. They have been around for ages and know their surface treatments. I knew this would not be cheap. I also knew it would take time... Surprise! Took less than a week and actually at quite a fair price. 4200 SEK, including VAT. A bit short of 500 USdollars for a rather thick layer of hard chrome. I´m happy it could be done locally!

OK, back to Sam in Jordbro! Here´s the result after Fintling´s chroming. We were both happy! Me, because I could afford it, Sam because their work was perfect! Not too much over chroming at the edges (that is a pain to grind off...) and also perfect thickness. Just right to be perfectly matched to the outer tube after the second grinding....

So, I left the tubes with Sam again... This time to be finished. Final grinding and a slight polish to that perfect "stanchion shine" Not too shiny but, for sure, free from pitting and rust.

Other than that, not much has happened on the project during the last month. I´m still gathering parts and trying to find missing bits and pieces. Extremely difficult! Not much around and people tend to keep stuff for themselves. I don´t blame them, I would do the same. The frame was finished a couple of weeks ago and sits on the lift ready to be assembled as soon as I can find the time for it. I also need to clean the fasteners and everything else for rezink.

Here´s what it looks like right now in the garage. Things piled up everywhere and the frame and parts sitting there, curing and waiting....

It doesn´t look too bad, though! Every time I pass it I want to start assembling stuff... I just have to be patient. There will be more time!

I recently had to empty another one of my small stashes of parts here on the island. That didn´t make it any easier! Now it is cramped for real! The H2 is going off to its new owner as soon as I can find the time to get it finished for him. That´ll ease up on things. My BMW R1200 GS and Wilma´s Z300 also have to camp in here. Plus the H1R project...

I NEED A BIGGER SHOP!!

Enough wining... Tomorrow I´m off for another training flight, This time to Chicago, my favorite town away from home. I feel at home most everywhere, but Chicago is special! Nice restaurants, nice people and that wonderful walkway along the lake.

When I get back I´ll start working on the wheels and the bolts and nuts...

Happy Easter everyone!

Your´s truly.

/Per

Inga kommentarer:

Skicka en kommentar