Part 1 of my upholstery-business-major-breakdown ended in anger a few days ago. The problem with my sewing machine was solved in a very simple and convenient way. I bought another one! I found a very nice, low mileage, vintage Husqvarna automatic sewing machine (just like the one I have...) on "Blocket", our big ad site here in Sweden. It was sold by an older guy working as a sewing machine servicing guy way south in Sweden. I ordered it, paid for it, Thursday, and had it here in Stockholm, Friday! How´s that for service!

Here it is, in its lovely vintage carrying box, with the super nice sixties manual and all accessories intact. It looks and feels as new. A little sewing sample from the servicing guy´s final tests still in there. Nice.

In the box was also the first "Bill of sale" for the machine. Since We´re all "vintage guys" here, I´ll share it with you. Imagine you had to pay 985 SEK (120 $US...) for a sewing machine in 1963! That must have been a lot of money at that time. On the other hand, the machine is still around and it works! Not much we produce today will still function as it was intended in 54 years...

I had a lot of expectations when I loaded the "new" machine with the same heavy duty thread and needle and started testing it. Smooth and nice action but still the same problems! As soon as I started sewing in slightly thicker material I had problems with the thread breaking and getting the thread tangled-up on the rear side of the work piece. I tried a lighter thread and needle. Same problem! Now what? I can´t keep on buying machines... There must be something else I´m doing wrong.

OK. Let´s start from the beginning, I have been able to do this before! There are some tips on troubleshooting in the manual and also instructions on how to load the machine properly. If the thread brakes easily, check the needle to be correctly inserted.... Aha! I had consistently put it in the wrong way! The flat surface on the needle´s upper part goes in AWAY from you, not TOWARDS you. Ok, slight mistake that cost me 300 bucks for a new machine! Always read the manual...

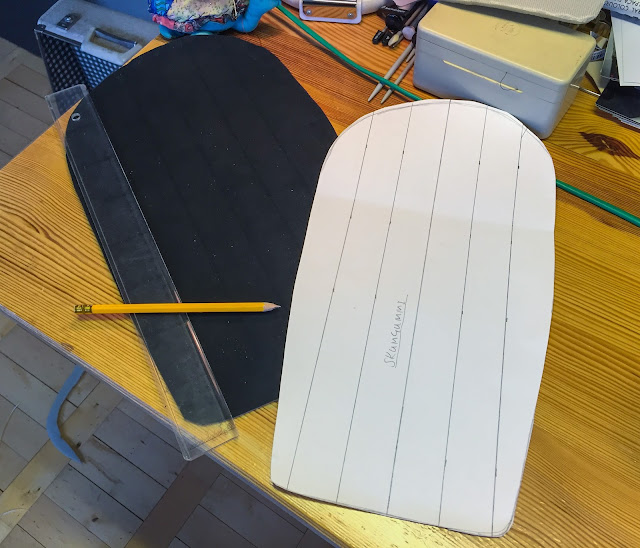

After a few hours of testing, adjusting, swearing, testing and adjusting again I finally got it working. With the Alcantara on top, the foam rubber lining underneath and a thick paper at the bottom to even the pressure on the lining I could finally sew the 5 seams on the seat surface late Friday afternoon.

I might have chosen a slightly too thick liner but it was the only type the upholstery guy had. Anyway, let´s see this first seat cover as a test! In the picture on the left you can see 3 out of 5 seams completed. I had it working OK now, but absolutely not perfectly. It still tangled sometimes so I had to start again right in the middle of a seam and that´s no good. Apparently it became easier to sew the second time in the same seam, because there was no tangling or thread-breaks at all.

And here´s the result of a full day at the sewing machine. Luckily I´m not a seamstress or tailor! That was also the thickest material I will have to sew in on this project. The sides of the cover will be Alcantara only and even doubled up it will be much easier to work with.

This is just a small peak in to our living room at present... My wife works a daytime job so I am able to roam the premises at free will during many hours. Now, it is time to clean things up a bit. Friday evening is approaching! We all like a cold beer at our local Chinese restaurant at 5 PM Fridays....

Saturday started out in a much better way. The top side of the seat being done (after two days of big problems...) and "only" the sides remaining to make. Same procedure here. Measure the template carefully, add a couple of centimeters seam allowance, cut the pieces and try to fit it together. There´s a seam on the sides just beneath the "back rest" part of the seat. These had to be sewn first. Before sewing the second one I had to carefully measure both the seat and back rest circumferences to get the side part absolutely correct in size. Being thorough here save´s lots of time later.

When those two seams were done it was time to see if the parts would fit together at all... They did, Surprisingly well at that! Starting to look like a seat cover, right?

Lots of stuff can still go wrong, have no doubt about it! Here I have started pinning the parts together. Frontside to frontside and the smaller part towards the backrest side and the larger towards the seat. Better look carefully if you do not want to do it all twice. The padding is also very visible in this picture. If you look closely you can see some of my tangles as well. As I said, this is an experiment. can I or can I not make it myself??

Here we can see the parts pinned together and ready to be sewn permanently. The qualified seamstress and tailor can see quite a few mistakes I have made. Me? I noticed them later!

My wife and her best friend were sitting next to me watching TV, cheering and commenting my work now and then.

"Why don´t you take a selfie?"

Why not? I took two of them. This, the first one, is the true me....

This second one is for facebook and Instagram use only. I was not this happy at all. But here it looks like I know what Iam doing and that is all that counts. Live your perfect life and show nothing of real interest to people.

Time to take a deep breath and focus on the task at hand. This is a very important seam. It holds the cover together and decides the shape of it to a large extent. A miss here will be very visible.

Here it is. Done! Not perfect, but not too friggin´bad either. I like the way it looks with the padding under the seams on top of the cover. It looks a little "softer" than the original one. Good or bad? That is up to the beholder.

The last part of the cover was sewing the edge of the sides. I had planned to incorporate a reinforcement for the push buttons on the sides. I put a strip of vinyl inside and pinned the edges according the measurements from the stock one.

The vinyl can be cut without loosing any strength and is easy to handle and glue together with other materials. Here I tried to make one of the "cutouts" for the rear dampers. That proved not to be too smart. It was extremely difficult to finish that rounded hole in a nice way. Big mistake! The stock cover has these "cutouts" but they are cut after sewing and has no finesse in the finish at all. I´ll just keep this. first try, as it is and remember what not to try next time.

The Saturday afternoon went fast with me strapped to the sewing machine and the girls cheering and applauding my work. They even said they were "inspired" to do some handiwork themselves. I can sum up this project in the project now... IF I ever feel like doing it again I have learned a thing or two these last couple of days.

1) If you´re going to try and make upholstery work, get a good sewing machine. Industrial grade, heavy duty or whatever you prefer to call it. Don´t even try on a 50 year old basic machine. It just will not work.

2) To save a whole lot of time and money... Trust your local upholstery venue with this kind of work! They know their stuff and will probably save you a heart attack and a bit of money ( since you don´t have to buy another sewing machine...)

Well, here it is. The finished product from Mr Olofsson´s upholstery services. Not too bad for an amateur, but to be frank, it won´t be good enough for anyone to use on a bike. I will just keep it as a reminder not to try this again. At least not in the near future.

One of the perks with writing this blog and also posting on Facebook now and then is I come in contact with lots of people around the world who actually knows something about the things I am trying to accomplish. Tomorrow I´m off on a journey up north in Sweden to meet up with a guy in Delsbo that can help me make some real good copies of the seat cover! He also has a super nice Kawasaki H1 1970 project for sale and I don´t mind having a look at that while we are at it. At the moment I´m kind of fed up trying to sew at all, which is actually very nice, since I have lots of work waiting in the garage to be finished. Wheels, brakes etc are a constant bad conscience down there. I really need to get it done. First off: a small trip north to fix some nice copies of the seat cover!

UPDATE 21NOV17:

Yesterday I went north to see Jens Kruper and Per Svedin at NCCR, Northern Classic Custom and Race AB. Jens is the owner of the venue together with his wife and daughter. I got the full tour and visited their workshop and store. The hours passed quickly looking at bikes like this:

This is a build NCCR made a few years back for the Big twin magazine. Iron head sportster engine with the most beautiful aluminium tank I have ever seen. A true masterpiece! A classic look with lots of modern accents. Check out the front brake and the head lights....

Look also at the leather work on these two bikes. Made by Per S, the other guy... I believe my seat cover copying is in good hands here, don´t you? The black seat on the rear sportster looks close to perfect for my application on the H1R. Leather is always leather and I kind of like it....

Here´s a close-up of the triple tree on the racer. Nice leather strap to hold the tank on the frame. Good attention to details!

After having coffee and a long chat in the workshop looking at the H1 1970 for sale (excellent find, by the way...!!), Per and I left for is house where he works as a tailor and sews the traditional folklore costumes used in Delsbo. Super exciting visit! Per is a master of his trade, that is 100% for sure. He is one of the few people around that still can make the chamois trousers and coats for these costumes. I got to see his work up close and was seriously impressed. I hope I´ll be able to share some pictures of his other work when I go back and get my seat covers. For now, I´ll show you ONE of his sewing machines. Slightly different from the one I used to make my own cover. I even got to try it.

Wow! Now we´re talking... I need one of those!

I trusted Per with my seat and covers and now he will reproduce one copy in suede leather and then we´ll see what material we will use on the other ones. I´m going to make at least 3 covers, one for me, one for Janne and one for my Canadian friend, Aaron. As Per will make his own templates for the covers I guess he can make more if someone needs it.

Thanks for reading!

/Per