It´s been way too long since my last post here on the blog. I´m so sorry about that! I´ve been very busy at work and also getting the house projects done. The basement room is coming to an end now as Wilma (our daughter) has actually moved in there and is getting the room ready in her own style. The other bathroom, further up in the house, is also getting close to being ready. Just a few more things left to do. I firmly believe it will all be done before Christmas. leaving me with 3 weeks of vacation from the 19th of December to the 13th of January with nothing else to do than being in the garage working on bikes.... And celebrating Christmas, of course!

Last time I mentioned progress being made in Malmoe and EBOS/Eptune on the engine. Well, it is soon finished! I´ve asked Ebbe for some pictures and a description of what he´s done so far and here´s the story.

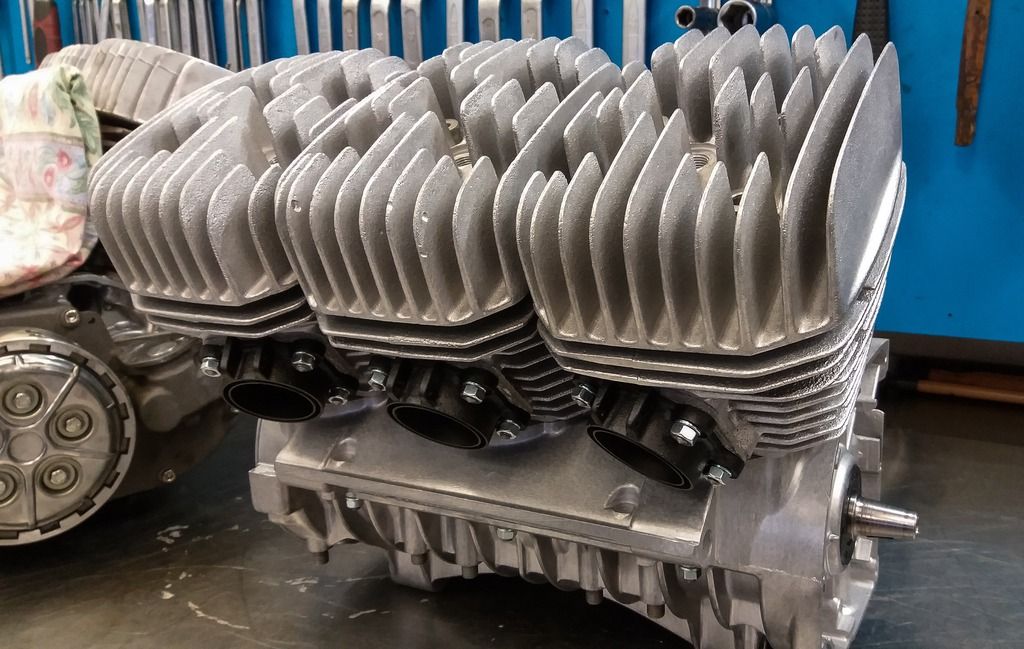

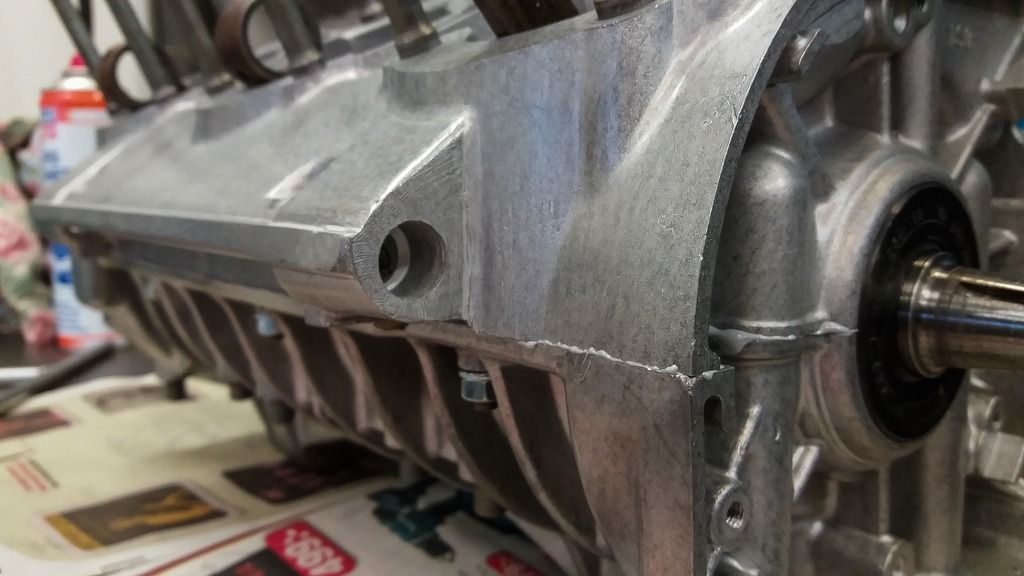

I did mention earlier that I went the complete restoration route with the engine. The cases went from EBOS/Eptune to Proswede in Hoerby to be glass media blasted and then "steel ball polished" in a vibrating machine, "tumbler". This treatment is superb when you want to create that "nucast" finish on aluminium parts. The blasting removes all the oxide and dirt from the cases and the polishing process in the vibrator seals the surface and creates this wonderful semi-gloss surface with just the right shine. I absolutely adore this treatment and use it on all engines I restore.

|

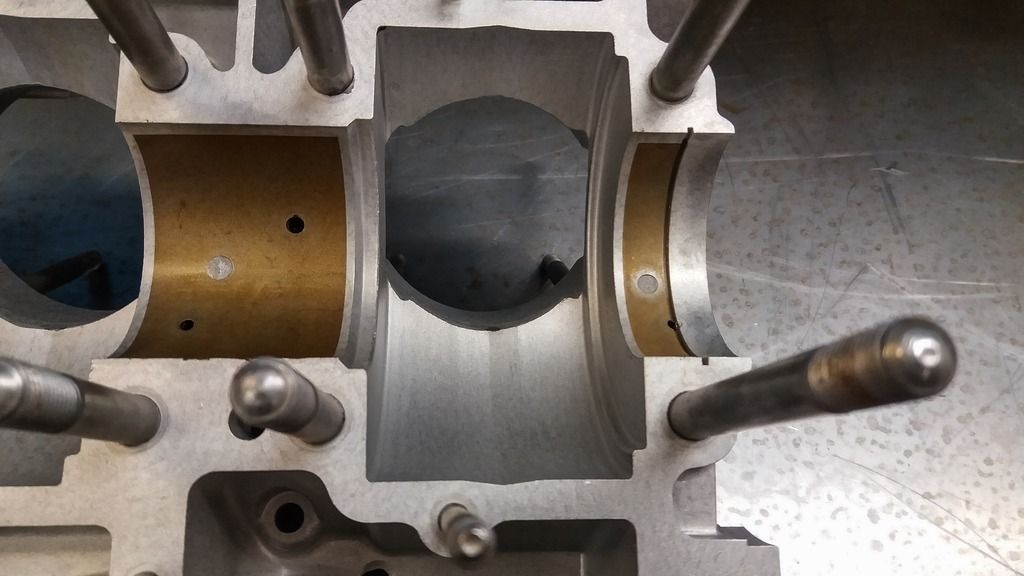

Shiny, steel ball polished surface on the engine interior.

|

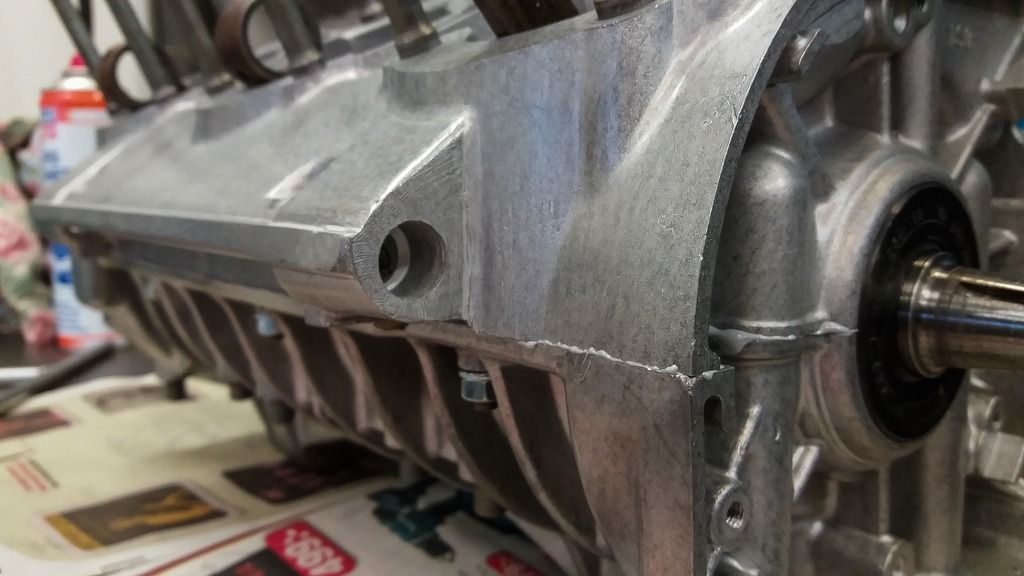

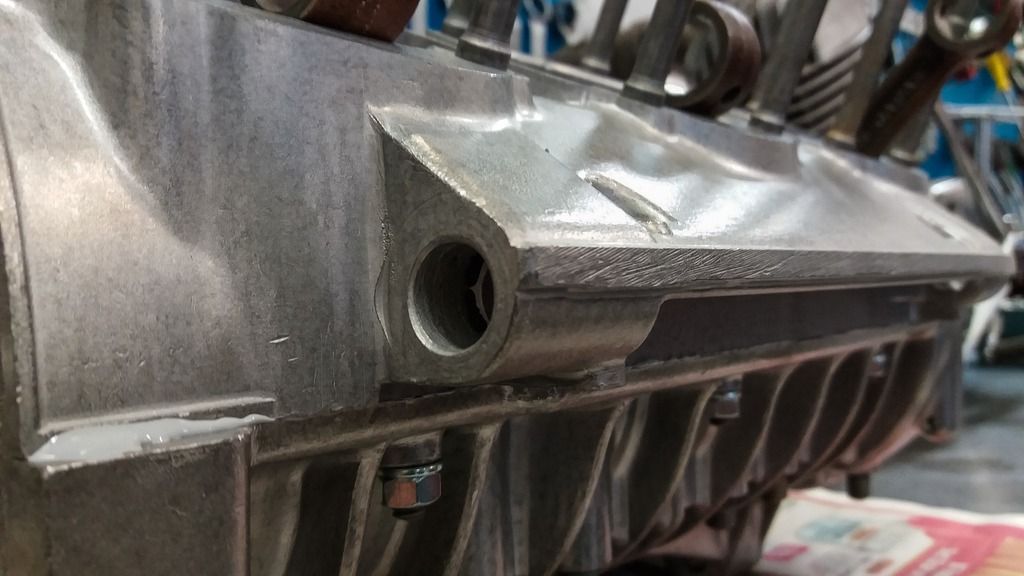

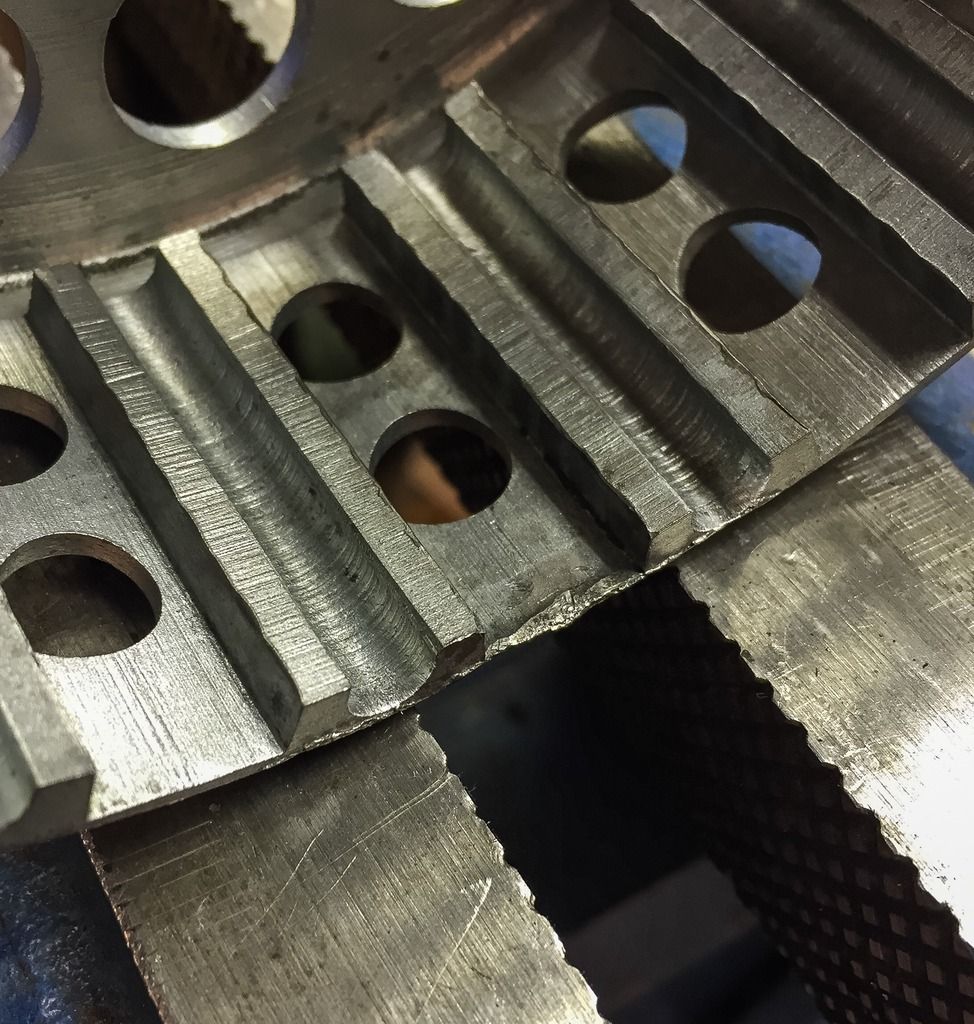

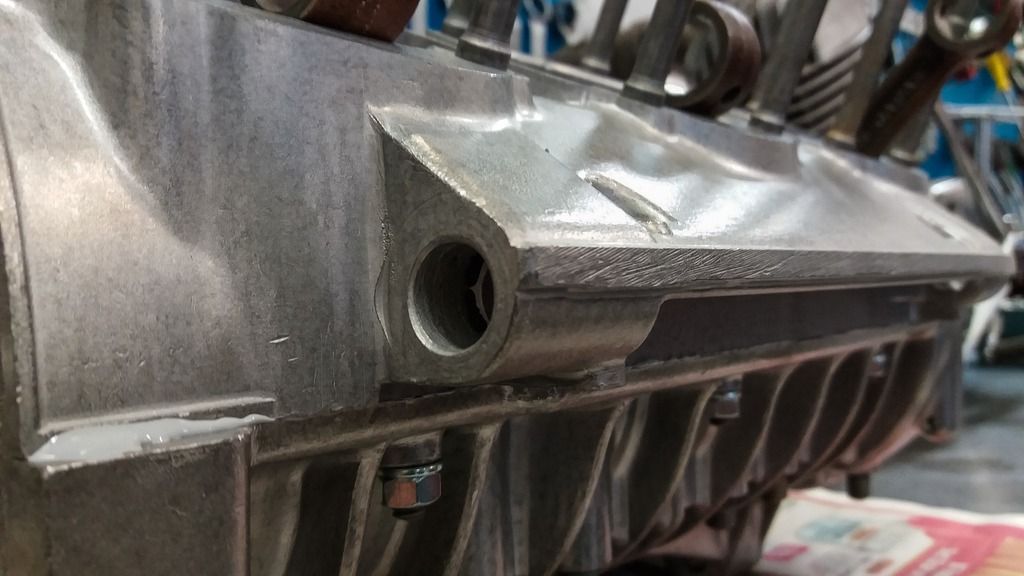

The cases were both in very good condition with only minor damage from the chain slapping the bottom case and one dowel pin being pushed into the case. One of the engine mounts were also damaged and a chip of the top case was missing.The chain damage was left as is (actually a sign of life I like to preserve) and the dowel pin was extracted by Ebbe and secured in place. The top case was welded by Ebbe with an absolutely stunning result:

|

| Now, let´s see.... Was it here it was damaged? |

|

| Or was it here.....?? Who can tell?! |

As you can see on the two pictures above, he is a master aluminium welder! The damage was on the left engine mount.

- " Well, I kind of like getting things back to the way they looked" , he explained to me. Yeah you did!

He also checked the crank and found the con rods to be OK, as was the big end bearings. The crank was seriously bent though, and needed straightening. An easy task for Ebbe! One of the main bearings was also shot and had to be replaced. Ebbe asked me if I had found any bearings.... I hadn´t.

- "Don´t worry, I´ll check and see what I can find" I started searching frantically myself, but came up short!

Two days later he e-mailed me the good news.

- "Found it, everything is OK" He is not known to be talkative, Ebbe. That mail made my day, for sure!

|

| Brand new roller bearing for an H1R crank, found in Malmoe. |

He had managed to find a perfect matching roller bearing to the H1R. That was really good news!

The work could continue. I sent him the gaskets I had sourced plus new piston rings, clutch plates ( a few of them anyway...) and some other bits and pieces needed for the motor. The gearbox was in good condition and only needed slight adjustments with shims to be perfect. New bearings and rollers, of course. Those are all standard parts and stock pieces at EBOS/Eptune.

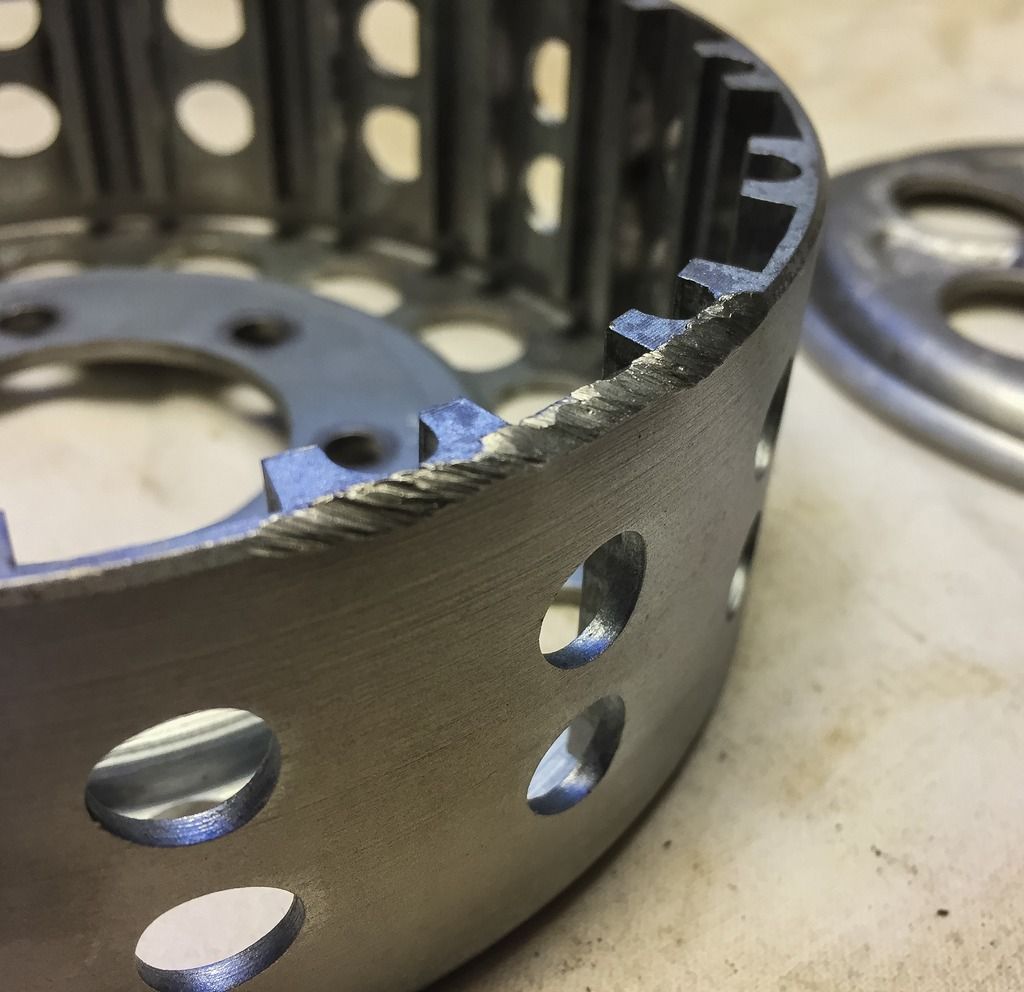

As the cases were getting ready to assemble he also had to tend to the axles, primary drive gears and the clutch. The axles were fine with a good media glass blast and will work fine as they are. No need to add material and grind to measurement. That was a relief. The clutch parts arrived to me via secure, insured mail....

- "You need to get these rezinked, and please clean out the pitting on the outer clutch plate"

Ok, finally I could do something myself!

|

| A package arrived with some goodies..... |

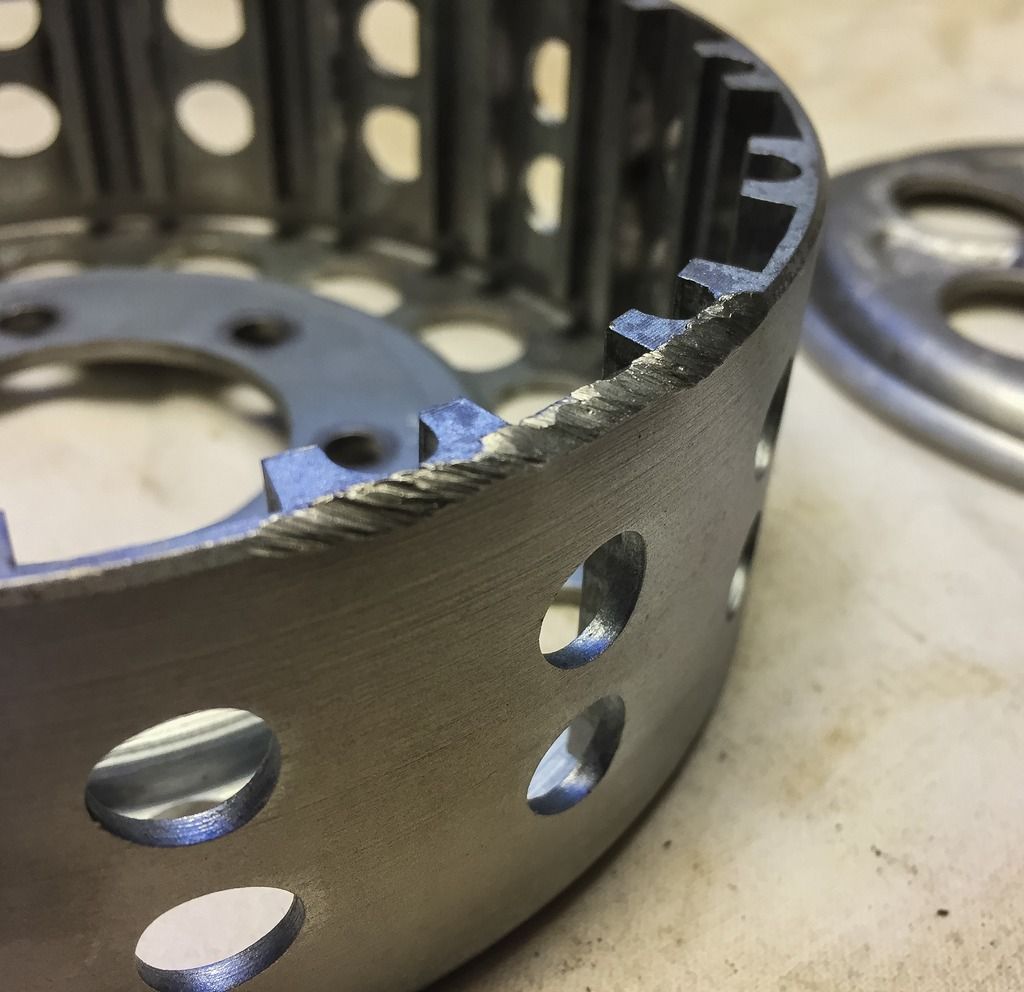

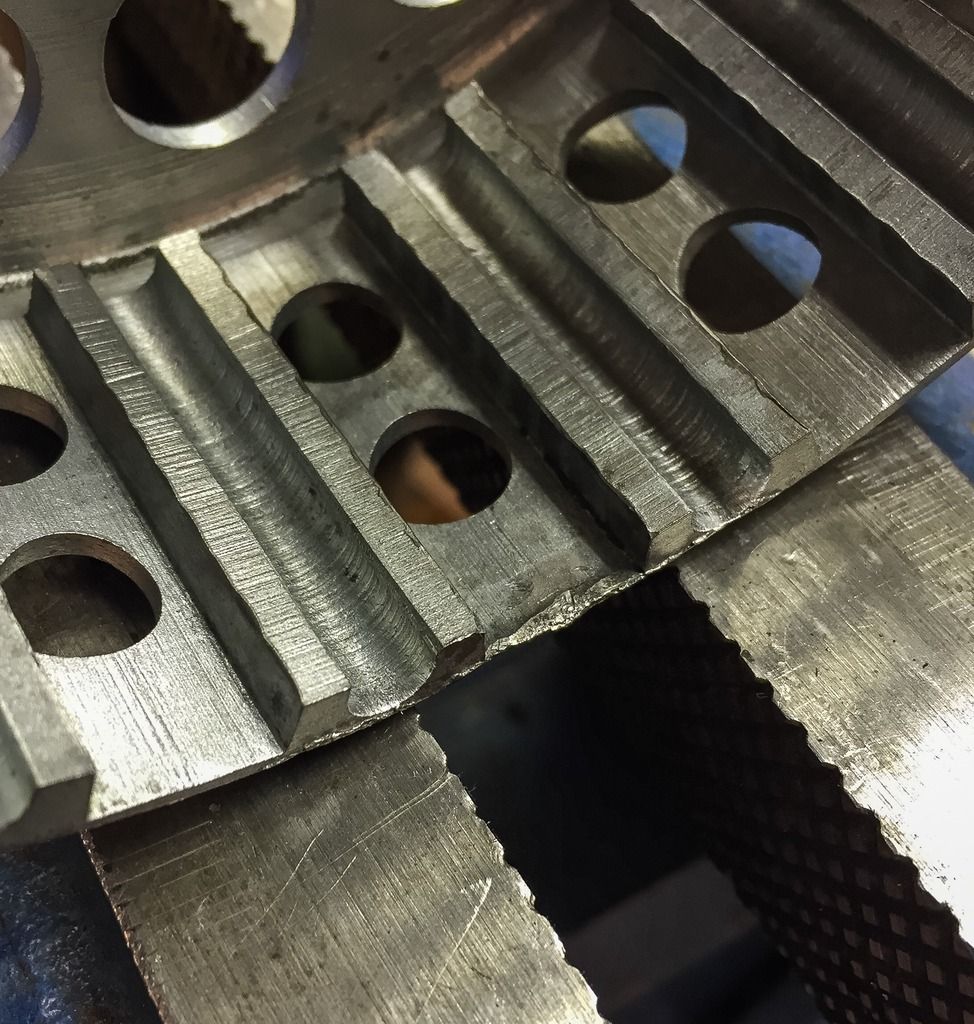

Here´s what the parts looked like. Bear in mind, all that´s been done here is glass blasting. My job was to get the parts straightened and sent off to the zink shop. The biggest problem was the clutch basket. The bike has been in quite a few crashes and I believe the clutch may have been replaced a few times. This one also bears marks after a close encounter with asphalt.

|

| Slight road rash on the clutch basket.... |

I tried to straighten it using a file and fine paper. Worked OK. I could get most of the damaged surface smooth enough to be acceptable. I did notice when looking closely that the basket was somewhat bent at the damaged spot. It had a "flat spot" that I needed to remove for the clutch plates to move freely.

|

| Straightening the clutch basket. |

It looks like a brutal method but it works fine. Many small, light blows with a small hammer/mallet does the trick. Give it a few beats, feel for result and keep at it until its round and smooth again. I can tell you it feels odd standing there beating on a clutch basket from an H1R like that... JEEZZ!

|

| Almost done. Just some filing to do |

I got the basket ready for zink and started on the clutch plate. Thank god I have my Dremel....

|

| Dremel is a wonderful machine! |

It took me about an hour to grind and sand the plate enough to an acceptable the surface. I could have spent 3 more hours and got it just perfectly smooth, but I don´t want that. Enough is enough! I polished the surface on my bench grinder using a buffing wheel and polishing wax. I think it got too shiny so I´ll ask Ebbe to glass blast it again when he gets it back. Or, what do you guys think?

|

| Bit too shiny, or? |

Anyway... Here´s what the parts looked like about two weeks ago when they left for rezink.

|

| Parts going to be rezinked (not the clutch plate...) |

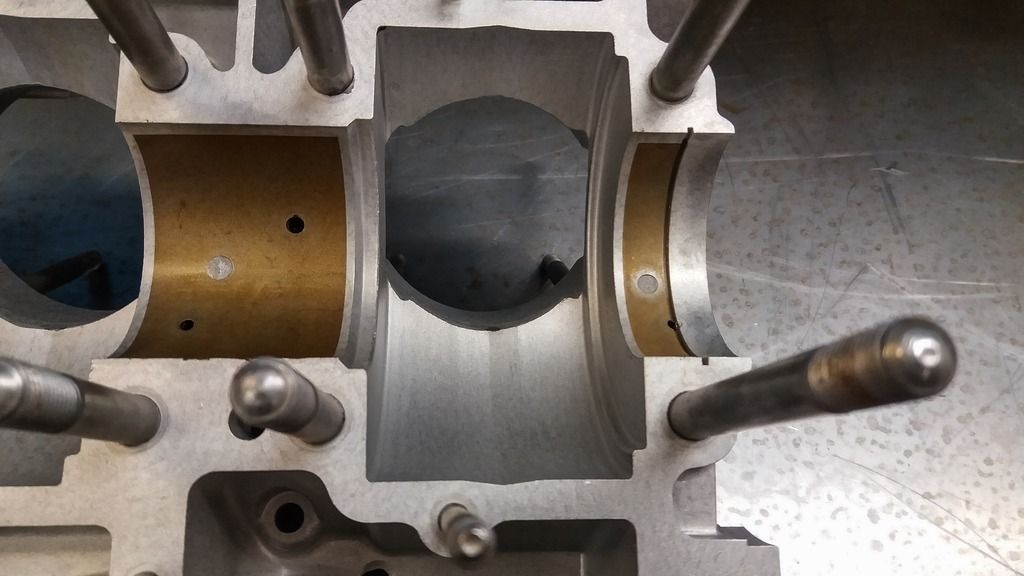

In the meantime, Ebbe had been hard at work with the engine. He had measured the pistons, piston rings (groove fitment and end gaps) and cylinders plus heads. Everything was within tolerance except the piston play in the cylinder with the new piston. Way to tight there! And a little bit on the large side on the other two. The solution? Hone the first cylinder to a correct play, glass blast the other two pistons ( makes them 1 hundredth of a millimeter larger). Piston rings were fine in all measurements.

Perfect! Everything ready to be assembled!

|

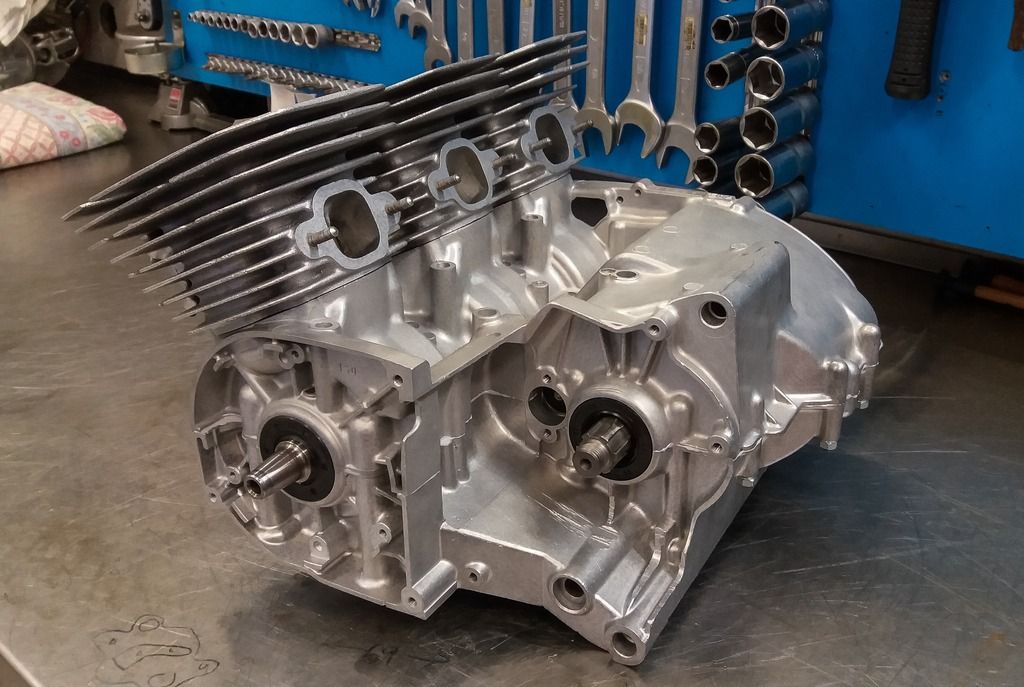

| Pornographic picture....? |

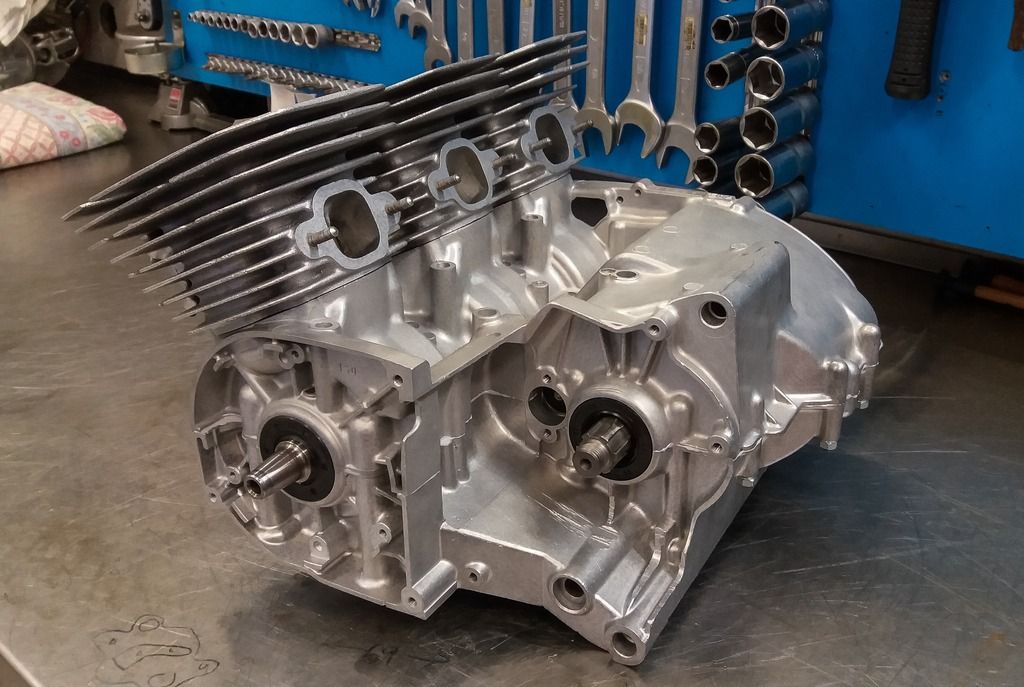

NOS cylinder base gaskets and on goes the barrels..... With that "nucast" steel ball polished surface I just love!

|

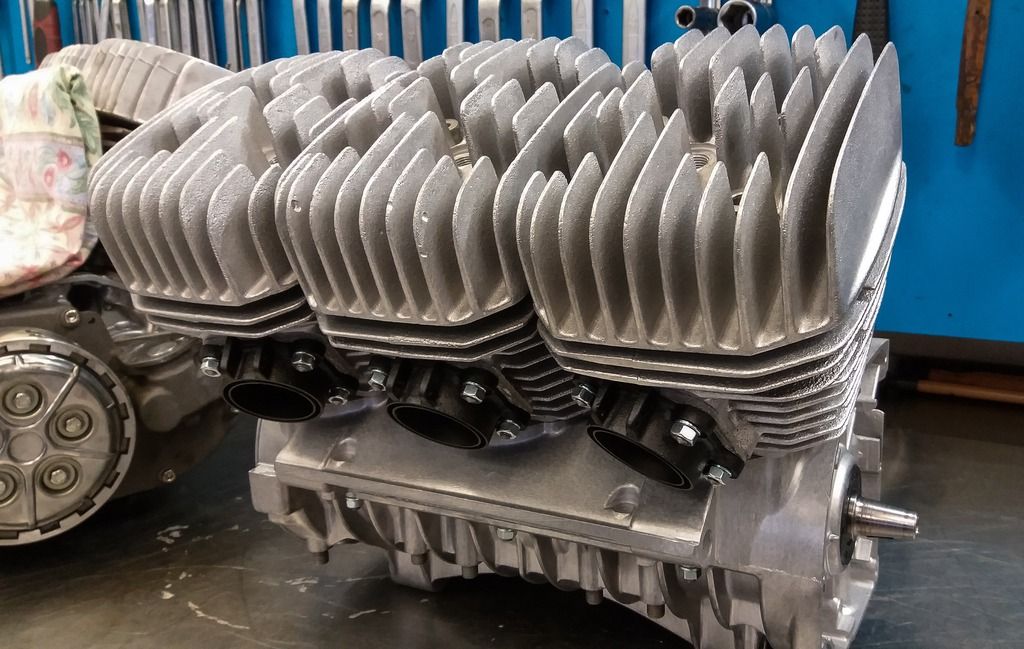

| Getting there.... |

I bought two sets of reproduced copper head gaskets from France and they were also sent to Malmoe. These are 1mm thick and makes the engine slightly weaker due to the lower compression ratio. During racing you could choose from a variety of thicknesses from 0,2 mm up to 1 mm in order to tune you engine perfectly for every race course. Well, I won´t be needing top performance when I´ll be driving it. I have never even been on a race track at all with a bike.... Interesting?!

|

| Starting to look like an engine again! |

In the last picture you can see what it looks like now... I think it´s superb! I´m more than happy with the work done by Ebbe so far. He even cleaned and painted the exhaust holders for me. I supplied NOS exhaust holder gaskets bought from Switzerland.... Parts are scarce for these bikes so I have to try all over the world. Sometimes I get lucky and sometimes I don´t! That´s all part of the hobby, right?

I think I´ll leave the story here and come back another day for the rest of it. More progress have been made on the engine and also on other parts....

Stay tuned for more, hopefully faster than last time!

Thanks for the update, I have been refreshing this page a lot the past 2 months..

SvaraRaderaI have never heard of glass blasting making a positive difference on tolerances. Can you send me a reference/info to back that up?

Thanks for your comment. In fact I wondered about that effect myself, but Ebbe claims that's what happens. I'm just an amateur mechanic with little or no experience in the field of glass blasting... I'll ask him for a confirmation and even ask for a test measurement when I go to visit him and pick up the engine. /Per

SvaraRaderaThis could come in usefull to squeeze more life out of my piston. It is within spec, but I'd like it to be a little tighter.

SvaraRaderaExcellent work on the engine, looks great. I'd agree the clutchpart is a little too shiny.

Thanks for the input! The clutch lid will be glass blasted again.... It is too shiny!

Radera/Per

Another wonderful chapter to follow in this rare story, thumbs up for letting us share the restoration of the "heart" of this rare bike

SvaraRaderaLonging for the next chapter ;)

Thnx/C